Delicious, Organic, and Local

How does it work behind the scenes? Let’s give the floor to the biologist.

Mycelium Selection

For local species, it is possible to clone the tissue of a wild mushroom in a petri dish. That’s exactly what we did for the winter variety of grey oyster we offer. It’s affectionately called T29, as we discovered it in February 2021 on the century-old beech tree in the large garden of Tournelle 29 in Orbe.

Mother cultures of exotic mycelium are produced and selected by specialized companies. These labs cultivate spores and select the most vigorous mycelium strains, which are already certified organic at this stage.

We chose two companies: one for its dynamism and youth, the other for its long history and expertise.

Once we have the mother culture, we clone it and distribute it onto several backup petri dishes so we can restart production at any time. These petri dishes have the incredible privilege of being stored in the mycothèques of the Federal Agronomic Research Station of Changins (RAC), now known as “Agroscope” .

Mycelium Amplification

From one of these petri dishes, with only a tiny amount of mycelium, we prepare what we call a liquid culture. This becomes our mycelium stock for starting all our production cultures. This liquid, which feeds the mycelium, is made of water, 3% organic honey from the region—or, for vegans, a version with 3% Demeter malt extract—and a pinch of vegetable peptones (predigested corn proteins).

As with everything we do with mycelium, we must work in absolutely sterile conditions, and everything that comes into contact with it must be sterilized. A small clean room was built for this purpose thanks to donations of unused scientific equipment from EPFL Lausanne and Neuchâtel, as well as the Lausanne School of Medicine.

These liquid cultures take about two weeks to mature and be ready to prepare the grain spawn.

Kept cool, they are used for several weeks until replaced.

Spawn Creation

The grain we use is simply organic wheat or rye from the region. After rehydration, we mix it with a bit of sawdust—the same that will later be used for the grow blocks—to already acclimate the mycelium to its future substrate.

After sterilization at 120°C and 2 bars, this substrate receives a small amount of liquid culture using a syringe.

The injected mycelium quickly colonizes the entire content, visiting every grain. That’s exactly what we want! Once the bag is fully colonized, after 2 to 4 weeks, we massage the bag to separate the grains clumped together by the mycelium, then move to the final step.

From the mother culture, almost two months have already passed.

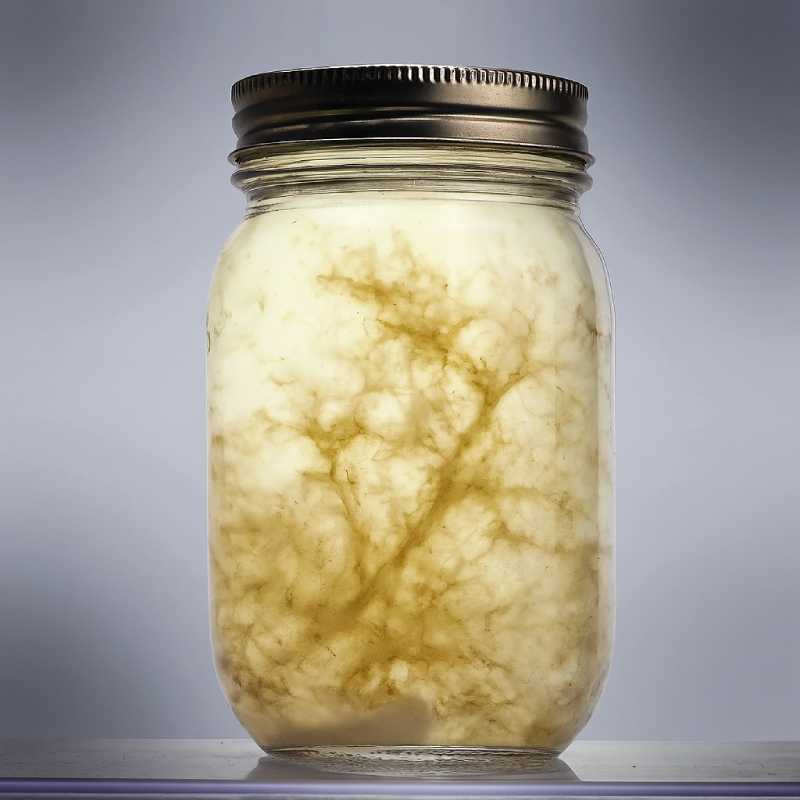

Colonization

Preparing the “blocks,” “sawdust cakes,” or simply “colonization substrates” is the most labor-intensive part of the process.

The block is made of sawdust (for the lignin and cellulose the mycelium will digest), wood chips (for aeration and as a support for mushroom growth), and wheat bran (as a nitrogen source to speed up the production of digestive enzymes essential for the mycelium). The wood is Swiss-certified (COBS), and the wheat bran is organic.

After mixing the components and filling the bags, the blocks are steam-sterilized for 24 hours. After an extra day of cooling in the clean room, they are inoculated with the previously prepared grains.

Once the grains are well mixed with the sawdust, the bags are sealed. The mycelium then begins its final colonization from each grain dispersed in the sawdust.

In an environment at 20–24°C, spherical colonization starts from each inoculation point and quickly spreads throughout the bag.

Two to eight weeks later, depending on the variety, the bag is completely white with mycelium, and we can move on to fruiting.

Fruiting

Once the block is fully colonized, it’s ready to go into the fruiting chamber. This is the stage at which you’ll find grow kits for home mushroom cultivation in stores.

Many small mushroom growers buy their blocks from large companies that do the upstream work, which makes economic sense given the enormous labor and expertise required from the initial culture to the finished block.

The block is then placed in a cooler environment to simulate autumn and pierced for oxygen supply. Unlike the common belief from button mushrooms, wood-loving mushrooms also need (morning) light for awakening and development. Finally, humidity of 82–95% depending on the species is needed for proper growth.

It takes only 7 to 14 days to see the first mushrooms appear and to harvest them!

Harvest

Each mushroom variety is harvested differently.

Some are cut, some are twisted, others are lifted—but the common point is that harvest timing is very precise. A daily check is therefore necessary for optimal quality.

Our blocks give two, sometimes three harvests before being recycled by local farms and returned to the fields.

More and more aspiring permaculturists also come to pick up our blocks for their gardens—they are freely available in our container in front of the lab 😉

And the cycle is complete!

To promote a very short circular economy, we have chosen to work with:

Liquid culture

Honey

Les miels Brunet

1315 La Sarraz

mielsbrunet.ch

Grain spawn

Rye grain

Rue du Merelez 1

1326 Juriens

fermearcenciel.ch

Substrate

Beech tree sawdust

Chenuz bois de feu

1147 Montricher

chenuzbois.ch

Substrate

Bran

Ferme du Petit Noyer

1433 Suchy

fermealanoix.ch

Block recycling

Ferme Arc-en-ciel

Rue du Merelez 1

1326 Juriens

fermearcenciel.ch

Or come pick some up for your compost!